ASME B313 gives below formula for Hydrotest pressure calculation Pt15PdRr Pt Hydrotest Pressure Pd Design Pressure Rr StS for pipe and component without established rating but shall not exceed 65 Ratio of component pressure rating at test pressure to the component pressure rating at component design temperature for components. MW 17197 HYDROTEST MANIFOLD DESIGN DEAR MEMBERS I NEED HELP FOR DESIGNING HYDROTEST MANIFOLD API 1104 WALL THICKNESS QUALIFICATI RE MW 17200Pipelines PetroWiki April.

Hydro Testing Manifold For Piping Systems Youtube

Pressures up to 60000psi 4200Bar.

. Does anyone knows if there is any requirement in ASME SEC VIII for test manifold utilize for piping hydrotesting - B313 piping to be inspected periodically and stamp after certain. The hydraulic test is done at ambient temperature it would not be. ASME B314 Liquid Pipeline Hydrotest Pressure Calculator Module.

18 ¼ 38 ½ 916 ¾ 1 Sizes are available. Simply enter your basic pipeline information to compute results according to AWWA C600 the installation standard. Compiled by Goutham Rathinam AweldI CWSIP 31 TWIUK Minimum Hydrostatic Testing.

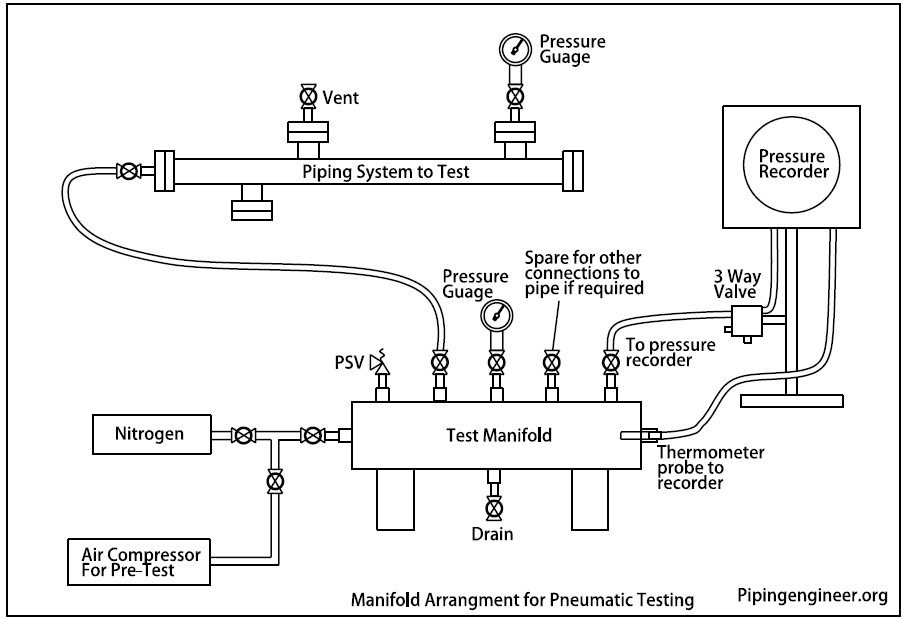

Show the Diagram of manifold for hydrotest test. TEST MANIFOLDS KEY FEATURES. Pump hose connects at one end and the other connects to the pipe.

A hydrostatic test is performed by using water as the test medium. Where P Hydrostatic test pressure in psi. Nominal Outside Diameter 32385 mm.

This covers Scope of Hydrostatic Testing of Piping or Pipelines test procedure test duration test pressure equipments required for hydro test acceptance criteria for hydro test test reports etc. Click to see full answer. This tool was developed for test engineers and contractors to plan the pipeline hydrostatic test operation.

Special demands and specifications often require special know and a lot of attention. Hoop stress is calculated using Barlows formula. Code Reference Maximum Permissible Test Pressure Minimum Test Hold Time Pressure Gages Test Temperature Limits Service Code Comparison of ASME Boiler and Pressure Vessel Codes Pressure Piping and API Standard Practices.

Pt minimum calculated hydrostatic test pressure kgcm2 P internal design pressure kgcm2 St allowable stress at test temperature kg cm2 S allowable stress at design temperature kg cm2. If the stress value of the vessel material at design temprature is less than the stress value at test temprature then hydrostatic pressure should increase proportionaly. PIPE HYDROSTATIC TEST MANIFOLD - 3000PSI.

Materials amp Welding MW 17197 Hydrotest manifold design. Medium High pressure connections. Qualifications and special machinery is available so that we can offer complete and competitive solutions to the market.

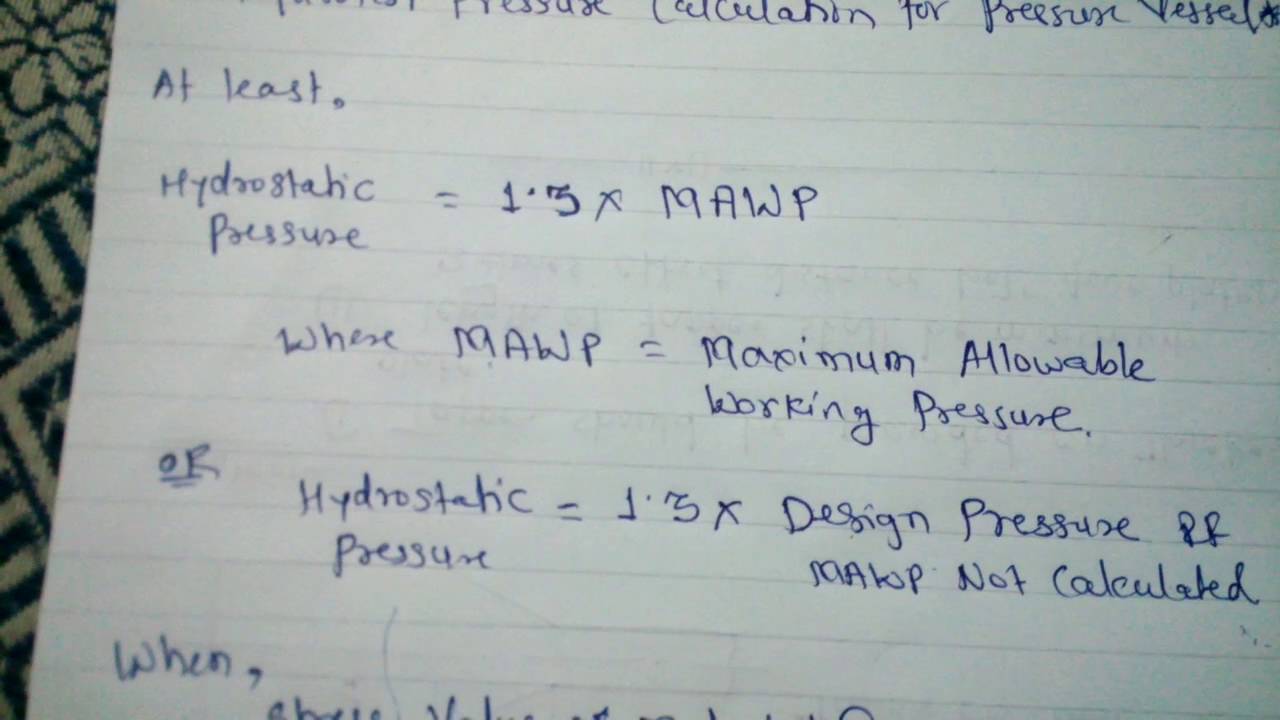

So Hydrostatic Pressure 13 x MAWP or Design Pressure x stress value at Test Temperature stress value at design temprature. Detailed comparison of API 5L 43 amp API 5L 44. A built in unloader valve lets the operator to turn up the pressure during test.

Hi All Need some help here. Manifolds Beside the fabrication of pipe spools we identified Manifolds as a separate product. See answer 1 Best Answer.

Welding Pressure Pipeliners and Piping Systems. Painting on joints prior to hydrotest Google Groups. P 2 148625 457 32385.

Api 1104 Hydrotest specification for line pipe engineering steel supplier dnv os f101 submarine pipeline systems t amp q pipeline safety seminar high grade pipe and hydrostatic testing procedures for facilities materials amp welding mw 17197 hydrotest manifold design hydro test pressure calculation for pressure vessel amp. Hydro-static Pressure 13 x Design Pressure. Topic Welding Industry Technical Discussions Hydrotest manifold.

Pneumatic test pressure is normally 10 higher than the design pressure. Calculation design optimized production. Hydro test Pressure Calculation for Pressure vessel amp Piping.

Design pressure10 barg at 400 oC design temperature hydraulic test pressure shall be higher than 15 barg specified by applicable code. Diameter in Pipeline Segment Length ft Test Pressure PSI Testing Allowance galhr Computed per latest edition ANSIAWWA C600 Rev 2010. As falllah explains for eg.

Api 1104 hydrotest Bing riverside resort net. S pipe wall stress in psi. API Spec 6A Flanged Equipment Hydrostatic Test Pressure.

In addition to above this covers basic information regarding minimum requirement. The elevation gradient along with the location and volume of the water source and the pipe design data should be used to determine the length and number of test segments. Hydro test Pressure Calculation for Pressure vessel amp Piping.

Hydrotest is recommended for high-pressure. Numerous configurations and unlimited port designs available. Select the appropriate line pipe schedule ASME or ISO etc and stress table API ASM DNV etc and material.

Hydrotest piping test manifold. S for 304 50 of 205 Nmm2 1025 Nmm2 1486 KSI 15KSI. Hydrostatic Test Pressure P 2St D.

Nominal Wall Thickness 457 mm. Safety requirements for pressure testing GS4. By fittoaflange Date 07-10-2008 1042.

Free standing robust frame design painted or Stainless Steel. For pneumatic testing the exclusion zones are significantly larger than for hydrotesting by orders of magnitude. Hydro test or Hydrostatic test is a type of pressure test performed on piping and pressure vessels to check system integrity under pressure conditions.

1 manifold socket welded is preferred test pressure range. A manifold which can be hired out individually or with a pump for testing pressures between 1000 and 3000psi. Calculate ASME B314 oil and liquid pipeline test pressure and hoop stress check for onshore and offshore pipelines.

This blog gives you brief information regarding hydrostatic testing of piping or pipelines. The safe distance may be increased and the temperature probe manifold and recorders may have to be set back further than 50 feet due to potential projectiles or extreme volumepressure. Current computation using 15 KSI.

- For a design temperature above the test temperature the minimum test pressure shall be as calculated by the following equation-S 15PSt Pt Where. The test gradient should be calculated to be sure the test pressure falls within the specified pressure.

Hydrostatic Testing Sciencedirect

Hydro Test Pressure Calculation For Pressure Vessel And Piping Video Dailymotion

Basic Hydrotesting Procedure Pressure Test Paano Gumawa Mg Testing Manifold Youtube

Pneumatic Testing Manifold Arrangement The Piping Engineering World

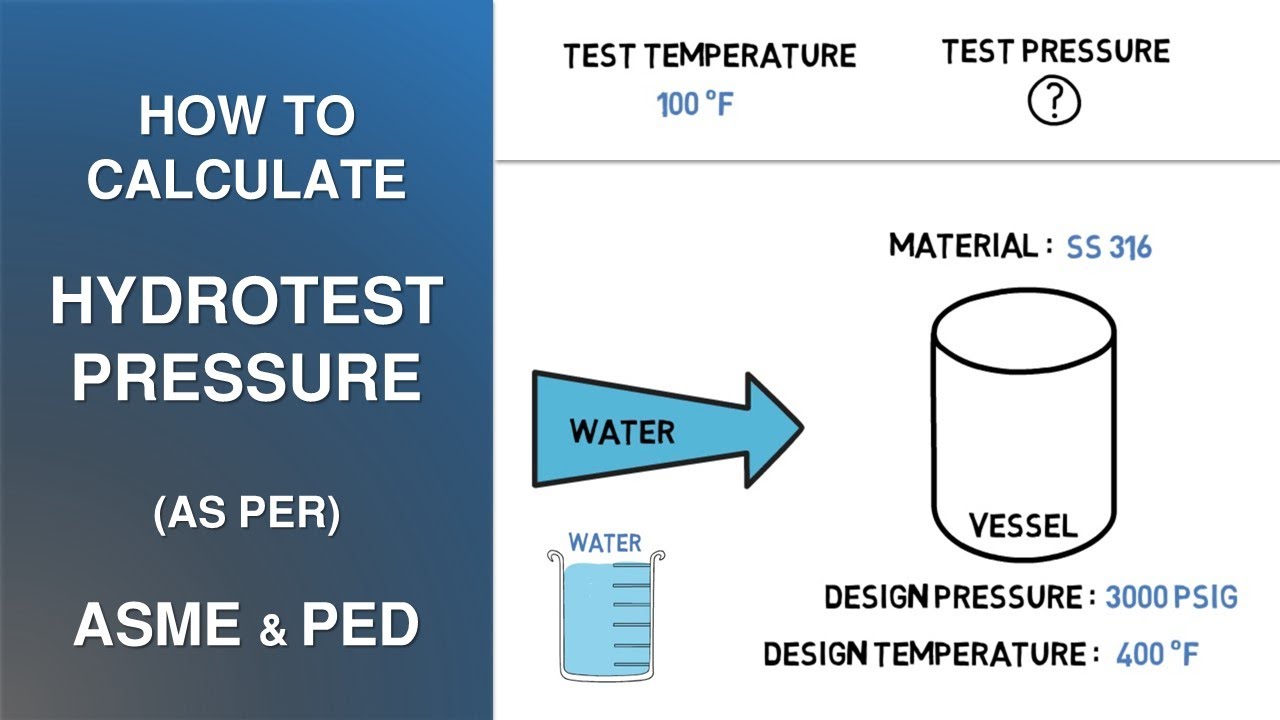

How To Calculate Hydrotest Pressure As Per Asme Ped Youtube

Hydro Test Manifold And Parts Pipingweldingndt Youtube

Hydro Test Pressure Calculation For Pressure Vessel Piping Youtube

![]()

Hydro Static Pressure Calculation For Pressure Vessels And Piping

0 comments

Post a Comment